五彩千年木 彩色细叶千年木是百合科,龙血树属。有三色千年木、七彩千年木。 彩色千年木,原产热带、亚热...

关于欧洲杯买球网站

欧洲杯买球网站(中国)有限公司官网

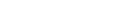

欧洲杯买球网站有限公司成立于2000年9月25日,公司主要从事花卉苗木的种植与销售、植物租赁、园林景观工程的设计与施工、园艺资材销售、花鸟鱼虫等。公司的管理人员都是在花卉行业摸爬滚打十余年之久的从业人员。本公司从改善大众生活环境出发,制定一家一园战略目标,让每个家庭都拥有一个属于...

查看更多 |

新闻中心

03-12

2019

03-12

2019

室内观叶植物冬季防寒防冻工作是正常管理中的一个重要技术环节。这项工作处理得当与否直接影响其栽培利用效...

03-12

2019

龙须兰也叫大花豆兰,原产于台湾,植株大小 8—15公分左右,花茎8公分。开花时期是春季到秋季,但花寿...

03-12

2019

在现代社会,人们经常因为鲜花宜人的外观和香味而以各种方式种植、购买和佩戴花卉。 人的一生中都会在各...

欧洲杯买球网站(中国)有限公司官网

欧洲杯买球网站(中国)有限公司官网